Changes in our production organization

Our production facilities are constantly upgraded to maintain world-class quality and competitiveness. The solutions deployed with this objective in mind include digital innovation, specialized plants and an international footprint.

India, a critical challenge

By setting up a production entity in India, Dassault Aviation continues to bolster its international development. We support Make in India, the Indian government policy designed to boost its economic development, especially cutting-edge industries, by encouraging foreign companies to set up local operations. With the sale of 36 Rafale fighters, a contract signed in 2016, we committed to long-term workload and technology transfers, as part of offset agreements. This commitment reflects the strategic partnership between France and India. The Make in India initiative will eventually be a competitiveness driver for one of the world’s largest and most dynamic economies.

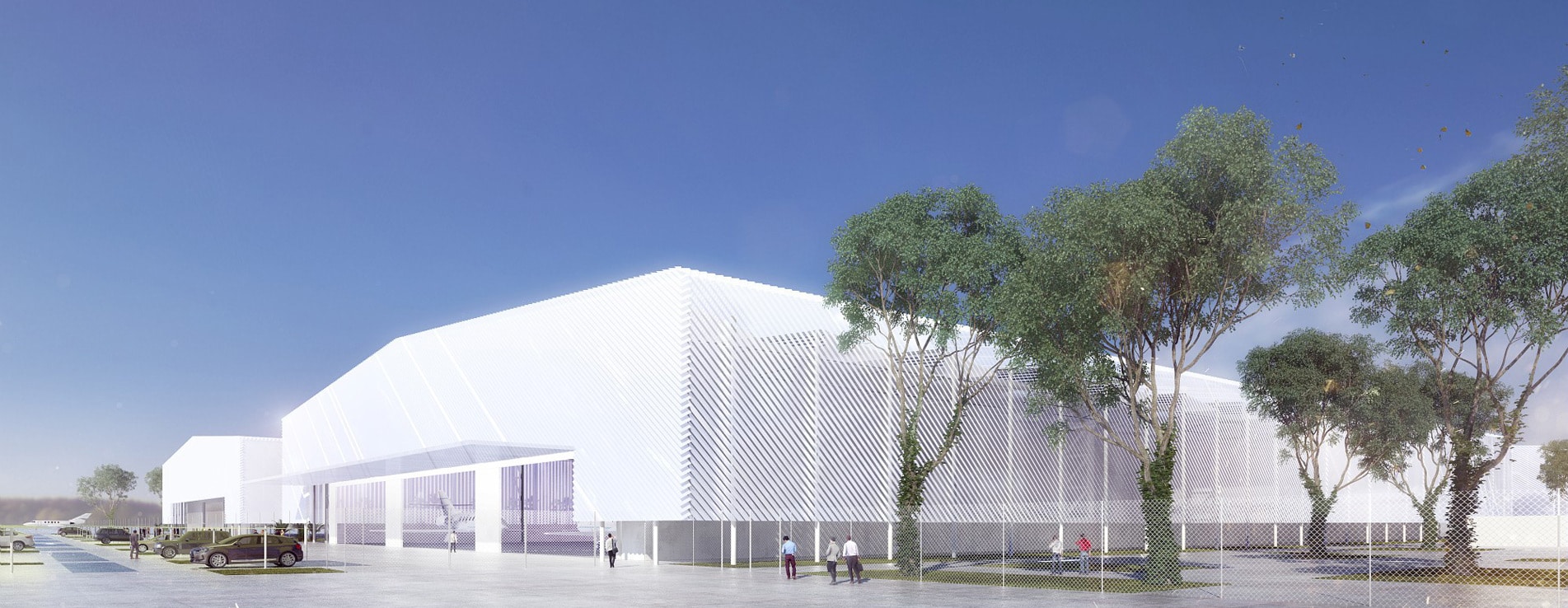

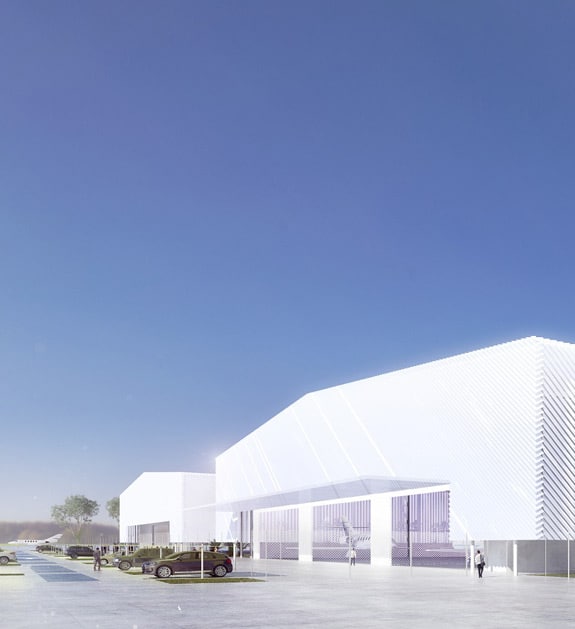

We started the construction of a plant in Nagpur, State of Maharashtra, in 2017. This facility represents the largest single foreign investment in India’s defense sector. It will first make parts for the Falcon 2000, then gradually ramp up production over the next five years. The Nagpur plant symbolizes our partnership with the Reliance Group, which resulted in the creation of a joint venture in early 2017, DRAL.

Our supply chain will benefit from new opportunities offered by our development in India. We are continuing operations designed to support our suppliers’ growth, so we can create a complete local ecosystem.

Boosting competitiveness

The drive to continuously improve our competitiveness is reflected in the organization of an integrated production system, based on an array of facilities specialized in strategic areas: metals, composites, flat products, etc. The aim is to further simplify our production organization and multiply synergies.

We have combined the SAP™ and Dassault Systèmes APRISO™ software packages into a single solution called “sapriso”, to unify manufacturing and logistics management, while also offering standardized connection to the European purchasing platform, AirSupply. Sapriso also synchronizes our production networks by offering enhanced visibility and real-time control of processes used by our own plants and suppliers. The result is a set of operational standards that continuously improve our production performance and also support connected manufacturing, a quick-response type organization of production and robotization.

Dassault Aviation also embraces Advanced Product Quality Planning, better known as APQP.

One Procurement

The One Procurement initiative reflects the same principle of unification applied to purchasing and procurement. As with digital tools, unifying processes makes us more efficient.

Concerning “make or buy” decisions, and more generally in relations with our partners, suppliers and subcontractors, we focus on long-term relationships based on a quality culture, meeting deadlines and competitiveness.

Production plants and offices